Focused on Permanent-Magnet Power, Shaping the Future of Oil & Gas

Modern Manufacturing Facility

High Standards · High Efficiency · Smart Manufacturing for the Future | A Solid Backbone for Premium Power Equipment

Shandong Yuheng Intelligent Dynamics Technology Co., Ltd. operates a modern manufacturing base planned and built to high industrial standards. The facility features a spacious footprint, clear functional zoning, and a well-structured layout for machining, assembly, testing, and logistics—enhancing efficiency while ensuring safe and orderly operations. Equipped with advanced machining equipment, automated assembly lines, and high-precision inspection & measurement instruments, our plant supports an end-to-end manufacturing workflow from key component machining and core assembly to complete system integration and commissioning—forming a strong foundation for consistent quality, stable performance, and controlled delivery.

Throughout manufacturing, we rely on a mature and disciplined production management system, implementing full-process control across critical procedures and major quality checkpoints. By embedding quality requirements into design transfer, machining, assembly execution, and final inspection, and by applying standardized processes with engineering-grade management, we ensure every motor and supporting control system meets defined technical standards and performance targets—reducing batch variation and operational risk from the source.

In addition, the facility includes an independent testing and laboratory center. For every outgoing unit, we conduct systematic performance testing, reliability verification, and endurance trials aligned with real application scenarios. Testing covers not only key performance metrics, but also long-duration continuous operation, adaptability under complex conditions, and stability in extreme environments—so each unit is thoroughly validated before delivery and better prepared for the high-reliability, continuous-duty demands of oil & gas and other industries.

Yuheng Dynamics remains committed to integrating modern manufacturing capability with rigorous engineering validation—turning manufacturing strength into core competitiveness. By delivering stable, reliable, high-efficiency and energy-saving power solutions, we help customers reduce O&M risk and total cost, while steadily advancing industries like oil & gas toward greener, more efficient, and more sustainable development.

High-Efficiency Motor Smart Production Line

The smart motor production line is one of Yuheng’s core manufacturing processes. It adopts automated control to enable end-to-end digital management—from stator winding and rotor machining to final assembly and inspection. With intelligent sorting and online quality monitoring, the process remains efficient and stable, ensuring precision and consistency for every unit. Automation significantly increases throughput and yield rate, providing strong support for high-volume, high-quality delivery.

High-Cleanliness Dust-Free Assembly Workshop

To ensure high-precision, high-reliability assembly of core components, we operate a cleanroom built to recognized industry standards. With stable temperature & humidity and a high-efficiency filtration system, the environment minimizes contamination risks during core assembly and winding. This effectively prevents dust and impurities from affecting performance, helping our products maintain stable operation even under high-load and demanding field conditions.

Fully Automated Vacuum Varnish Impregnation & Curing

We utilize fully automated vacuum impregnation equipment for deep varnish treatment of stators. Through vacuum extraction and pressure penetration, insulating varnish uniformly permeates the winding structure—significantly improving insulation strength, moisture/dust resistance, and long-term reliability. The automated curing system further shortens production cycles while ensuring every motor we manufacture delivers excellent electrical performance and stable operation.

Smart Coating & Constant-Temperature Drying Room

Our coating room integrates intelligent spraying with constant-temperature drying to enhance both appearance quality and protective performance. Controlled temperature and humidity ensure uniform coating adhesion, smooth surface finish, and strong corrosion resistance. Combined with an environmentally friendly purification system, emissions of dust and VOCs are reduced to support green manufacturing. Each unit undergoes strict appearance and weather-resistance checks prior to shipment—balancing durability with aesthetics.

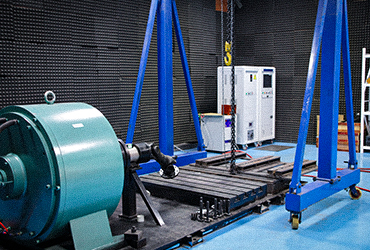

Professional Motor Acoustic & Performance Test Room

The acoustic test room is equipped with high-precision sound and vibration monitoring systems to comprehensively evaluate noise, temperature rise, efficiency, and load performance during operation. By simulating different working conditions, we verify performance from multiple angles to ensure compliance with stringent industrial standards. Advanced noise-reduction engineering and rigorous testing procedures are a key pillar behind Yuheng’s quality reputation.

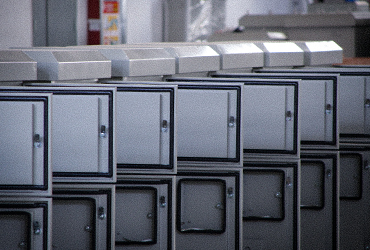

Intelligent Electrical Control Assembly & Commissioning Line

The electrical control line covers cabinet assembly, wiring inspection, functional debugging, and burn-in testing. With modular design and lean workstation layout, it improves both efficiency and assembly precision. Every control system is strictly tested before delivery to ensure stable, efficient, and remotely controllable operation under complex field conditions such as oilfields—supporting the real needs of intelligent oil & gas production.