Powering with Permanent Magnets, Leading the Future of Oil & Gas

Industrial Control Network Software Platform (ICSP)

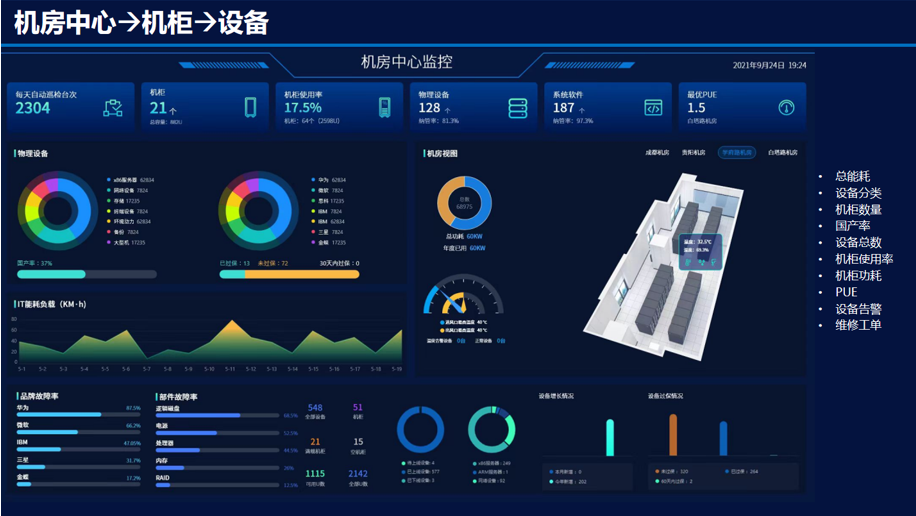

Integrated O&M Platform - Operational Assurance

End-to-end monitoring, early warning, and analysis from terminals to networks and servers, building a stable and reliable operational assurance system.

Connect. Visualize. Control. Sustain.

ICSP (Industrial Control Software Platform) is Yuheng’s industrial control network software platform built for field operations. Centered on “device connectivity + data governance + access security + closed-loop O&M,” it consolidates distributed motors, VFDs, control cabinets, sensors, and station control systems into a single visualized network—enabling integrated management of remote monitoring, alarm linkage, parameter deployment, strategy control, maintenance work orders, and operational reporting.

Where ICSP Fits

Oil & gas production sites, pumping stations & pipeline networks, mixing & blended transport, produced-fluid treatment, station electrical retrofits, device fleet control and energy-efficient operations.

Asset Registry & Topology

Integrated modeling for sites, regions, devices, and links; asset codes, parameter templates, and batch import make large-scale deployment easier.

Real-Time Data & Trends

Live acquisition, trend curves, and comparative analytics for key parameters; quickly locate anomalies by device/site/shift dimensions.

Alarm Linkage & Closure

Multi-level thresholds, composite rules, suppression/delay strategies; SMS/email/app notifications; alarms → work orders → reviews are fully traceable.

Permissions & Audit

Role-based access, organizational isolation, and operational auditing; full records for critical parameter deployments meet internal controls and field safety requirements.

Unified O&M View: From Systems to Data Center Infrastructure

Covering OS, databases, middleware, networks, and data-center infrastructure to enable multi-layer, traceable unified operations management.

Edge-Cloud Architecture: Stability First, Real-Time by Design

ICSP adopts a layered architecture of “field edge acquisition + station gateway + platform services”: reliable on-site acquisition and buffering prevent data gaps, while the platform handles governance, alarms, control strategies, and multi-end visualization—suited for weak networks and scalable operations alike.

Architecture Overview

Core Modules (Default Package)

- Device Access & Protocol Management

- Asset Registry & Parameter Templates

- Real-Time Monitoring & Historical Trends

- Alarm Center & Notifications

- Remote Parameter Deployment & Control

- Work Orders & Inspection Logs

- Energy Analytics & Report Export

- Role Permissions & Audit Traceability

Typical Use Cases: From “Seeing the Issue” to “Solving It”

ICSP is not only for visualization—it focuses on control strategies and closed-loop O&M, upgrading incident handling from experience-based to repeatable processes.

Oilfield Production Sites

Unified monitoring across wells and sites; centralized management for pumping units and drive systems; alarm-triggered shutdown protection reduces unplanned outages.

Energy Optimization for Drive Systems

Energy breakdown, efficiency benchmarking; supports automatic strategy switching by operating conditions and parameter curves to reduce peak power and cost volatility.

Remote O&M and Inspections

Alarms automatically generate work orders; inspections, spares, and repair records become equipment history files—reducing travel and improving response speed.

Reliability & Security: Long-Run Stability is the Real Capability

For industrial networks and control systems, we follow engineering principles of “stability first, controlled access, and traceable operations” to keep the system running steadily under complex networks and harsh operating conditions.

Key Platform Capabilities

Security & Audit

Want to Apply ICSP to Your Station / Pumping Site / Device Fleet?

Based on your equipment types, communication conditions, and management goals, we can propose an onboarding list, point-table templates, deployment architecture, and rollout timeline.