Powering with Permanent Magnets, Leading the Oil & Gas Future

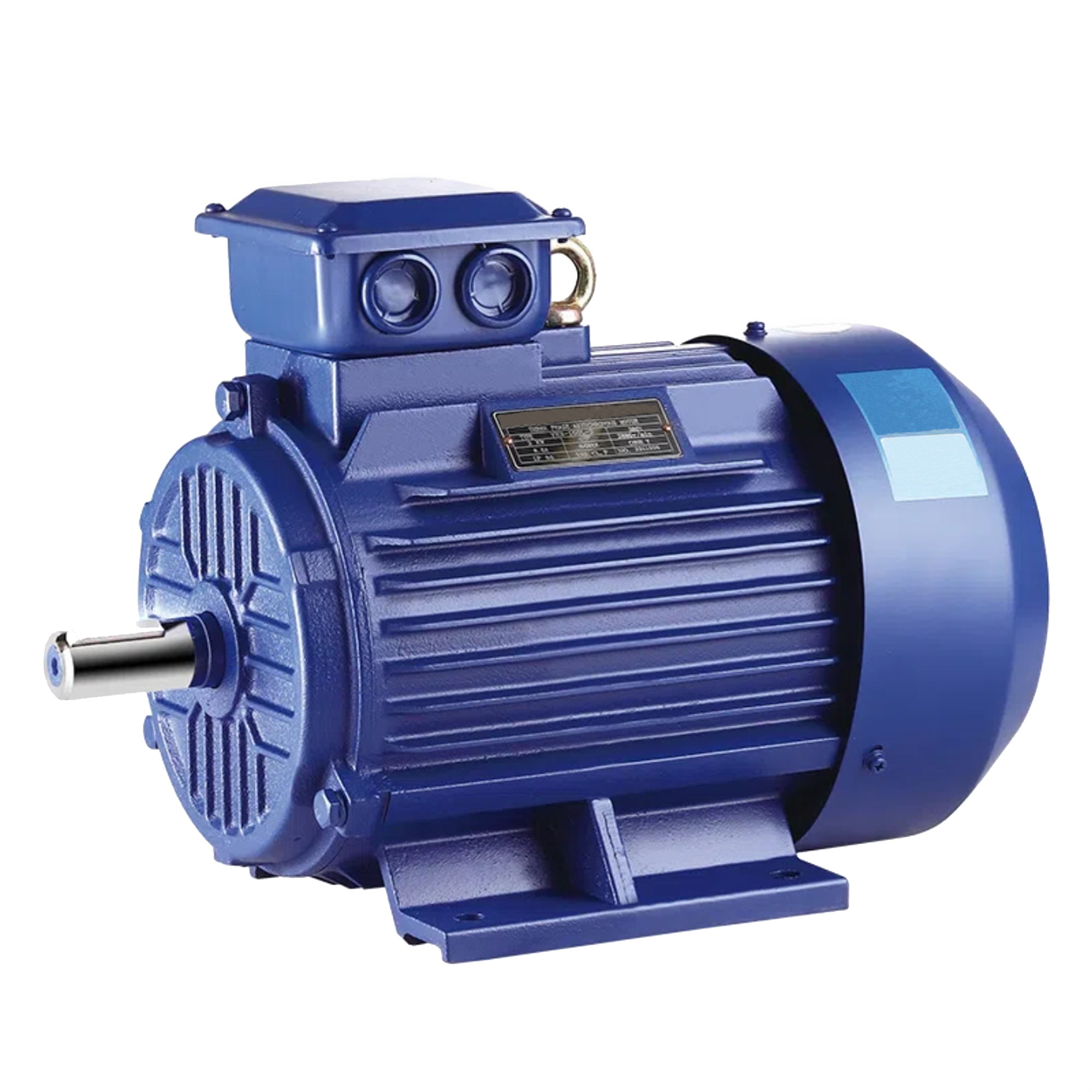

VFD Variable-Speed Three-Phase Permanent Magnet Synchronous Motor

Key Features

Technical Specifications

Product Overview

The VFD variable-speed three-phase permanent magnet synchronous motor is a high-performance power solution designed for high efficiency, wide-range speed regulation, and long-term continuous operation. It is widely used in oil & gas production equipment, pump station transportation, mixing systems, and various industrial loads requiring VFD speed control. By adopting high-performance permanent magnet materials and an optimized electromagnetic structure, the motor maintains high efficiency and power factor under different frequency conditions, providing a stable foundation for overall system energy saving.

In response to harmonics and electromagnetic excitation characteristics introduced by VFD outputs, this series adopts an internal transverse magnetic circuit structure and enhances adaptability to harmonic power supplies through design measures such as air magnetic isolation slots; meanwhile, corona-resistant enameled wire and an optimized insulation system are selected to effectively reduce risks of vibration and heating, improving reliability and service life performance under complex operating conditions.

In terms of noise and vibration control, the product maintains an average noise level below 70 dB and vibration below 1.0 mm/s, making it suitable for applications with higher requirements for on-site comfort and equipment stability. Combined with VFD control, the motor achieves smooth speed regulation over a wide frequency range, with high operating efficiency and significant energy-saving effects, meeting diverse needs from operating condition optimization to energy-saving retrofits.

Overall, the VFD variable-speed three-phase permanent magnet synchronous motor provides a more reliable and economical drive upgrade path for oil & gas and industrial sites through its comprehensive capabilities of “high efficiency, low losses, low noise, and long service life.”

Model List

| Motor Model | Frame Size | Rated Power | Rated Torque (N·m) |

Rated Voltage (V) |

Rated Speed (r/min) |

Declared Efficiency (%) |

Rated Frequency (Hz) |

Protection | Duty | Energy Grade | Insulation Class | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (kW) | (HP) | |||||||||||

| TYCP-22-3000 | 180M | 22 | 30 | 70.0 | 380/660 | 3000 | 95.9 | 200 | IP55 | S1 | 1 | F |

| TYCP-37-3000 | 200L2 | 37 | 50 | 117.8 | 380/660 | 3000 | 96.3 | 200 | IP55 | S1 | 1 | F |

| TYCP-45-3000 | 225M | 45 | 60 | 143.3 | 380/660 | 3000 | 96.4 | 200 | IP55 | S1 | 1 | F |

| TYCP-75-3000 | 280S | 75 | 101 | 238.8 | 380/660 | 3000 | 96.6 | 200 | IP55 | S1 | 1 | F |

| TYCP-15-2500 | 160M2 | 15 | 20 | 57.3 | 380/660 | 2500 | 95.3 | 166.7 | IP55 | S1 | 1 | F |

| TYCP-18.5-2500 | 160L | 18.5 | 25 | 70.7 | 380/660 | 2500 | 95.6 | 166.7 | IP55 | S1 | 1 | F |

| TYCP-22-2500 | 180M | 22 | 30 | 84.0 | 380/660 | 2500 | 95.9 | 166.7 | IP55 | S1 | 1 | F |

| TYCP-30-2500 | 200L1 | 30 | 40 | 114.6 | 380/660 | 2500 | 96.1 | 166.7 | IP55 | S1 | 1 | F |

| TYCP-22-2000 | 180L1 | 22 | 30 | 105.1 | 380/660 | 2000 | 95.8 | 133.3 | IP55 | S1 | 1 | F |

| TYCP-37-2000 | 225S | 37 | 50 | 176.7 | 380/660 | 2000 | 96.2 | 133.3 | IP55 | S1 | 1 | F |

| TYCP-45-2000 | 225M | 45 | 60 | 214.9 | 380/660 | 2000 | 96.3 | 133.3 | IP55 | S1 | 1 | F |

| TYCP-75-2000 | 280S | 75 | 101 | 358.1 | 380/660 | 2000 | 96.5 | 133.3 | IP55 | S1 | 1 | F |

| TYCP-37-1500 | 225S | 37 | 50 | 235.6 | 380/660 | 1500 | 95.3 | 100 | IP55 | S1 | 1 | F |

| TYCP-45-1500 | 225M | 45 | 60 | 286.5 | 380/660 | 1500 | 95.5 | 100 | IP55 | S1 | 1 | F |

| TYCP-55-1500 | 250M | 55 | 75 | 350.2 | 380/660 | 1500 | 95.8 | 100 | IP55 | S1 | 1 | F |

| TYCP-75-1500 | 280S | 75 | 101 | 477.2 | 380/660 | 1500 | 96.0 | 100 | IP55 | S1 | 1 | F |

| TYCP-37-1000 | 250M | 37 | 50 | 353.4 | 380/660 | 1000 | 96.0 | 66.7 | IP55 | S1 | 1 | F |

| TYCP-45-1000 | 280S | 45 | 60 | 429.8 | 380/660 | 1000 | 94.2 | 66.7 | IP55 | S1 | 1 | F |

| TYCP-75-1000 | 315S | 75 | 101 | 716.3 | 380/660 | 1000 | 96.4 | 66.7 | IP55 | S1 | 1 | F |

| TYCP-90-1000 | 315M | 90 | 121 | 859.5 | 380/660 | 1000 | 96.5 | 66.7 | IP55 | S1 | 1 | F |

| TYCP-37-500 | 280M | 37 | 50 | 706.7 | 380/660 | 500 | 93.9 | 33.3 | IP55 | S1 | 1 | F |

| TYCP-45-500 | 315M | 45 | 60 | 859.5 | 380/660 | 500 | 94.2 | 33.3 | IP55 | S1 | 1 | F |

| TYCP-75-500 | 355M2 | 75 | 101 | 1432.5 | 380/660 | 500 | 94.7 | 33.3 | IP55 | S1 | 1 | F |

| TYCP-90-500 | 355L1 | 90 | 121 | 1719.0 | 380/660 | 500 | 94.7 | 33.3 | IP55 | S1 | 1 | F |