Powered by Permanent Magnet Technology, Shaping the Future of Oil & Gas

Engineering Validation First—So Every Innovation Can Run for the Long Term

At Yuheng Dynamics, we follow a technology path anchored in engineering validation. We do not stop at concepts or “lab-only” breakthroughs built on isolated performance indicators. Guided by a systematic R&D philosophy of predictable design + verifiable results + repeatable delivery, we introduce real-world constraints and field boundary conditions from the very beginning—so each innovation is backed by clear theory, a practical validation route, and sustainable engineering feasibility.

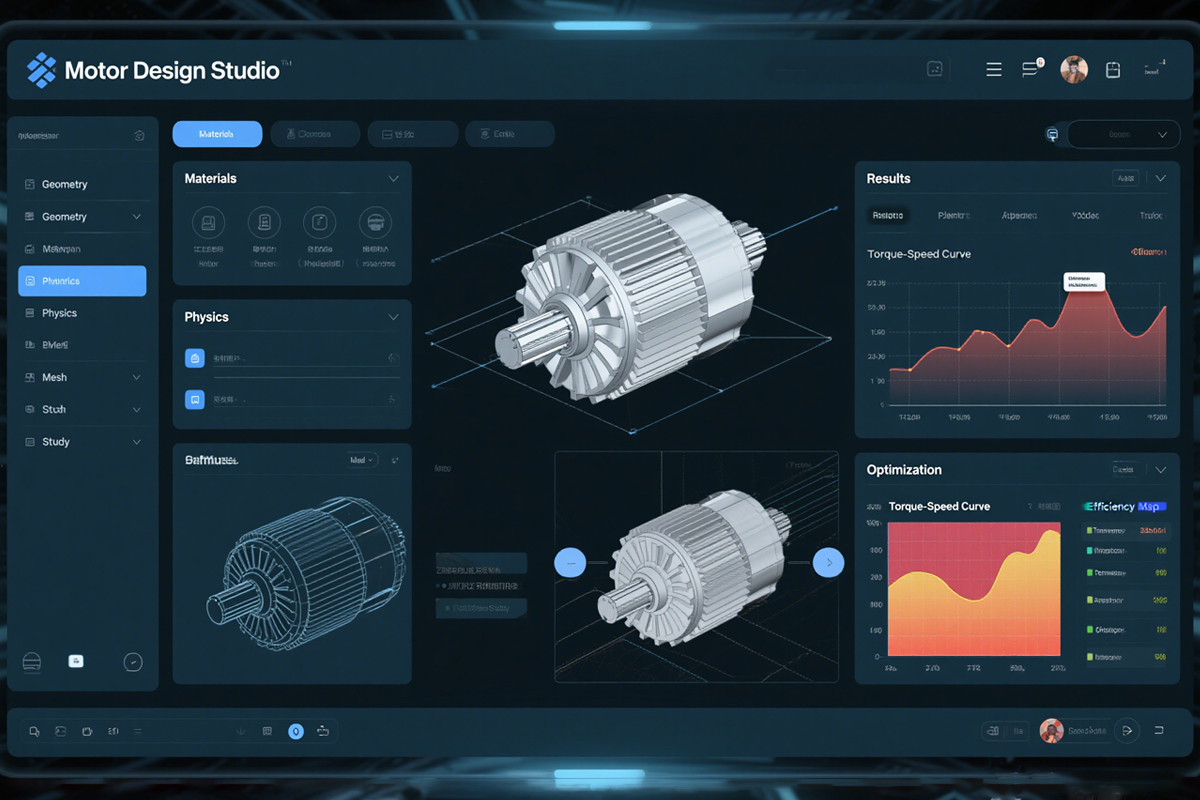

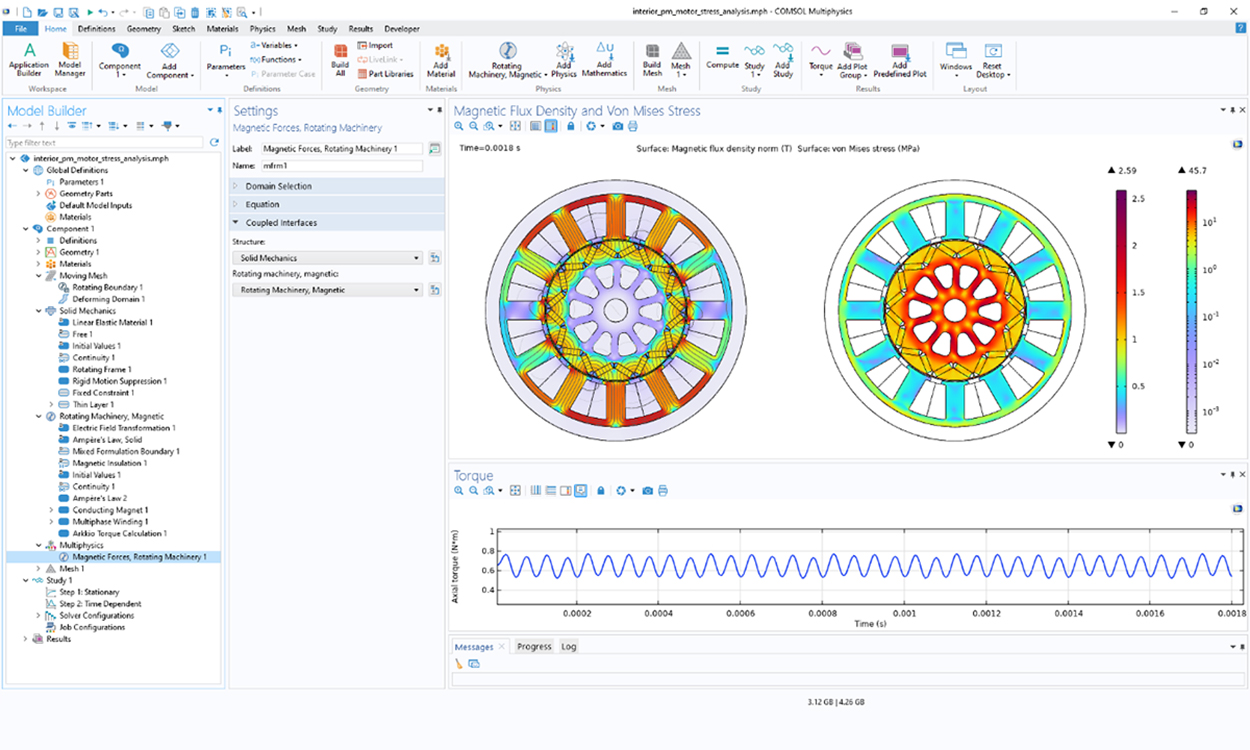

Around permanent-magnet motors and their control electronics and system platforms, we have built a closed-loop capability spanning electromagnetic simulation, structural & thermal analysis, prototype manufacturing, bench testing, system integration, and long-term field monitoring. By continuously comparing and calibrating simulation outcomes with test data, we refine design models until predicted performance matches real operation with high consistency.

After delivery, we further integrate ongoing field data—load fluctuations, environmental changes, and long-term reliability behavior—into our R&D feedback loop. That means every new generation is built on what truly happens in the field, not on assumptions.

Electromagnetics & Efficiency Optimization

For low-speed heavy-load and frequent start-stop duty, we optimize magnetic circuits, slot/pole combinations, winding forms, and control strategies as a system—reducing torque ripple and additional losses, while keeping high efficiency and smooth operation even in the low-speed region.

Thermal Design & Reliability Margin

Considering high temperature, dust, limited ventilation, and continuous outdoor operation, we build thermal models from simulation plus measured feedback—optimizing heat paths and structure to secure thermal margin and insulation-life safety boundaries under long-term high-load operation.

Materials & Process System

With lifecycle thinking, we systematically match permanent-magnet materials, electrical steel, insulation systems, and bearing systems—and solidify key process parameters into repeatable standards to minimize batch variation and make consistency part of our delivery capability.

Validation & Field Closed-Loop

Performance tests, reliability verification, and endurance trials turn R&D assumptions into measurable results. Combined with field data feedback, we iterate continuously so upgrades and long-term maintenance have clear engineering evidence behind them.

Motor R&D: Simulation-Driven Design—Reliability Delivered Through Engineering Detail

In PMSM development, Yuheng Dynamics focuses on system-level co-optimization rather than pushing a single metric to extremes. For typical industrial scenarios such as low-speed, high-torque duty, we evaluate electromagnetic behavior, thermal distribution, structural strength, and vibration/noise control within one unified framework from the start. This avoids common engineering mismatches—such as strong electromagnetic performance with insufficient cooling, or adequate torque with excessive vibration.

With multi-physics co-simulation, we quantify key performance early and refine design boundaries through iterative tuning. Bench testing and measured data validation make core indicators—efficiency, torque density, temperature rise, and operational smoothness— highly predictable at the design stage, reducing later trial-and-error and field risk. On materials and manufacturing, we apply lifecycle-based selection logic: demagnetization resistance of magnets, insulation thermal class, bearing life and lubrication are assessed as a system. Verified critical process parameters are then solidified into traceable engineering standards, ensuring consistent performance across batches and production cycles. For customers, that means not only “a prototype that runs,” but also “stable at scale and economical over the long run.”

Control & Drive R&D: 20+ Years in Extreme Environments—Refined into High-Reliability System Capability

In control and drive systems, Yuheng Dynamics brings over two decades of engineering experience designing control cabinets for extreme conditions—high heat, severe cold, strong electromagnetic interference, unstable grid quality, and outdoor unattended operation. Unlike lab-centric approaches, we use real duty conditions as boundary constraints from day one—accounting for uncertainty factors and failure modes, and reserving sufficient engineering redundancy and safety margin.

At the architecture stage, we build complete protection strategies and safety boundaries in parallel—covering electrical topology, power path planning, control hierarchy, and derating/protection mechanisms under abnormal conditions. With engineering-grade component selection, rational thermal management, and integrated dust/moisture/corrosion protection, we significantly improve anti-disturbance capability and long-term stability under high load and long duty cycles—reducing system-level risk from single-point failures.

We also draw from proven methods and engineering principles accumulated in defense-related projects with higher safety and reliability requirements, selectively transferring them into industrial control systems. Enhanced redundancy, failure-mode analysis, and harsh-duty validation raise reliability, stability, and maintainability standards. As one of the early teams in China to develop and deploy large-scale PCS systems, we have formed reusable methodology for multi-device coordinated control, power distribution/management, and system-level efficiency optimization—supporting stable scheduling and operation in complex industrial scenarios.

On standards and platforms, Yuheng Dynamics has participated in work related to the national standard Technical Requirements for IoT Systems for Onshore Oil & Gas Production, with deep understanding of IoT architecture, field data acquisition, edge control, and system integration. This “standards insight + engineering practice” capability enables our solutions to go beyond single-cabinet reliability—offering scalability, compatibility, and platform readiness for seamless integration with upper-layer digital systems, remote monitoring platforms, and future intelligent upgrades.

In long-term delivery and operation, we treat the control platform as a continuously evolving engineering system rather than one-time hardware. By organizing runtime status, fault logs, and maintenance data systematically, we calibrate design assumptions and control strategies in reverse. With remote monitoring, parameter traceability, and software upgradability, the platform can adapt to new duty conditions without hardware replacement—significantly extending effective service life. For customers, this reduces downtime and maintenance cost while leaving ample room for digital upgrades and expansion, making the control system a stable foundation across the full equipment lifecycle.